Beers

The history of beer production stretches back millennia, with evidence suggesting that beer was brewed as early as 13,000 years ago in the Middle East. Ancient civilizations like the Sumerians, Egyptians, and Babylonians held beer in high regard, incorporating it into daily life and religious rituals and even using it as payment. Early brewing methods were rudimentary, often involving the fermentation of grains like barley or wheat in simple vessels. Over centuries, brewing techniques evolved, with significant advancements occurring in monasteries during the Middle Ages, where monks refined processes and experimented with ingredients, notably the adoption of hops as a flavoring and preservative. The Industrial Revolution brought about large-scale production with advancements in steam power, refrigeration, and quality control measures like the hydrometer and thermometer. Today, beer production is a global industry, blending ancient traditions with modern technology to create various styles.

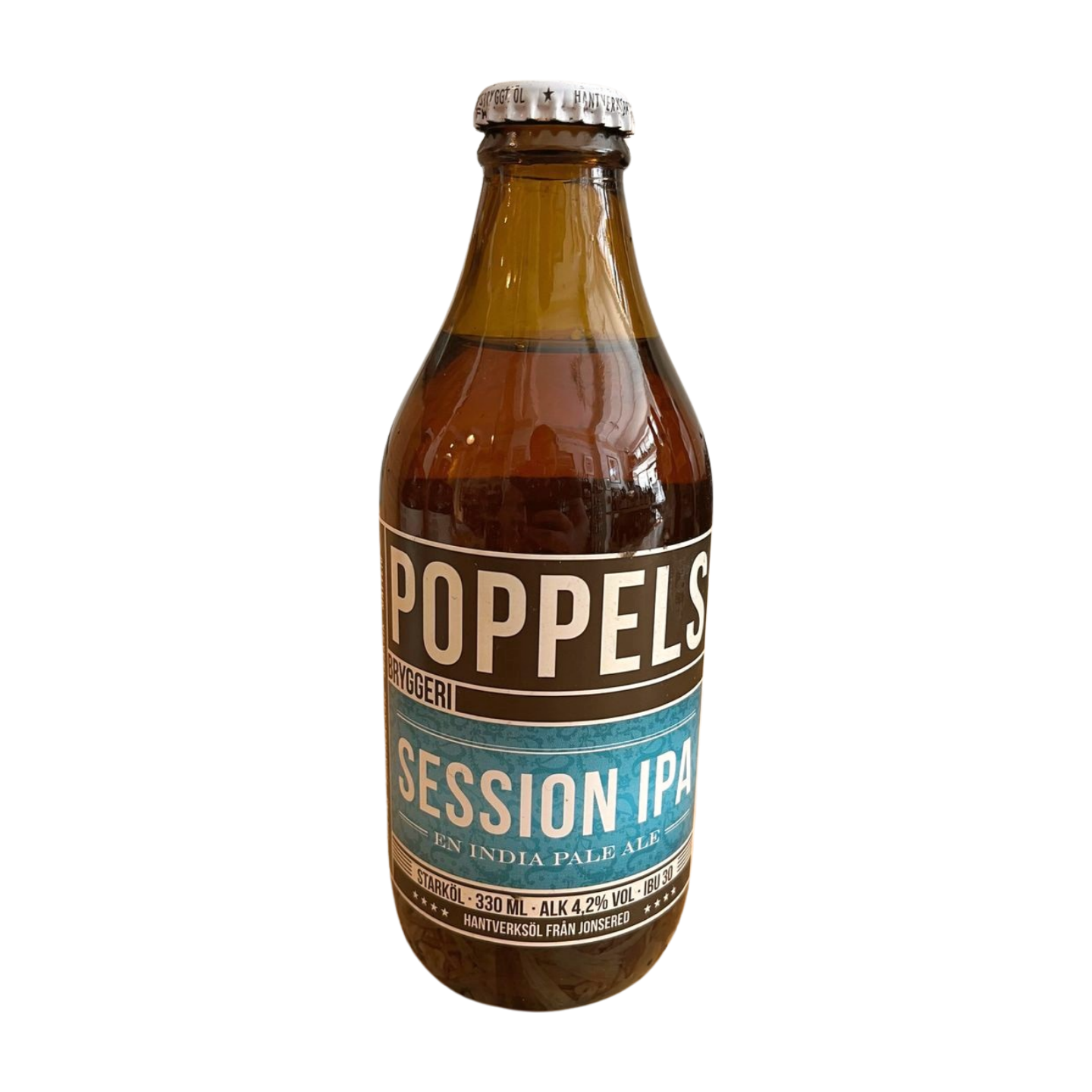

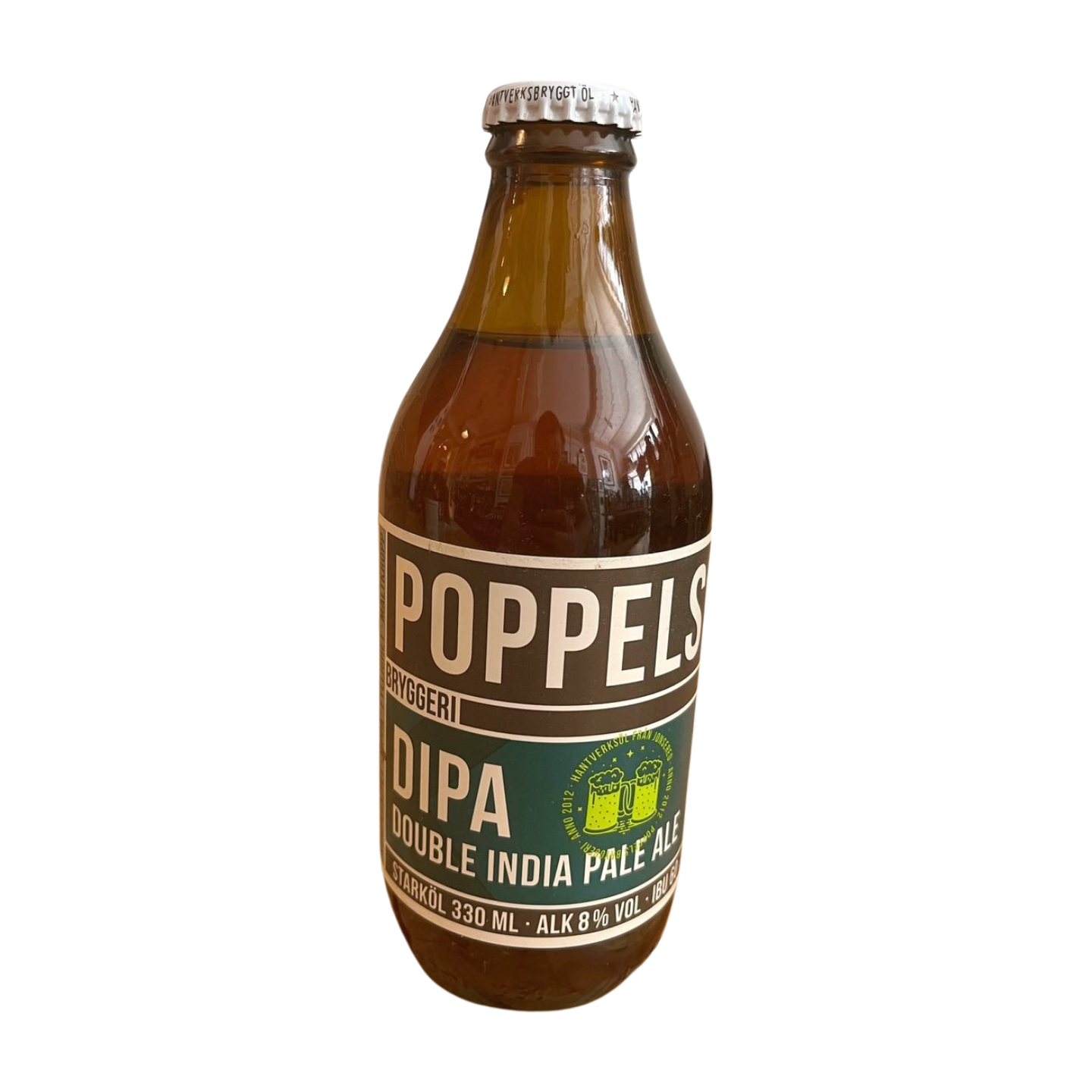

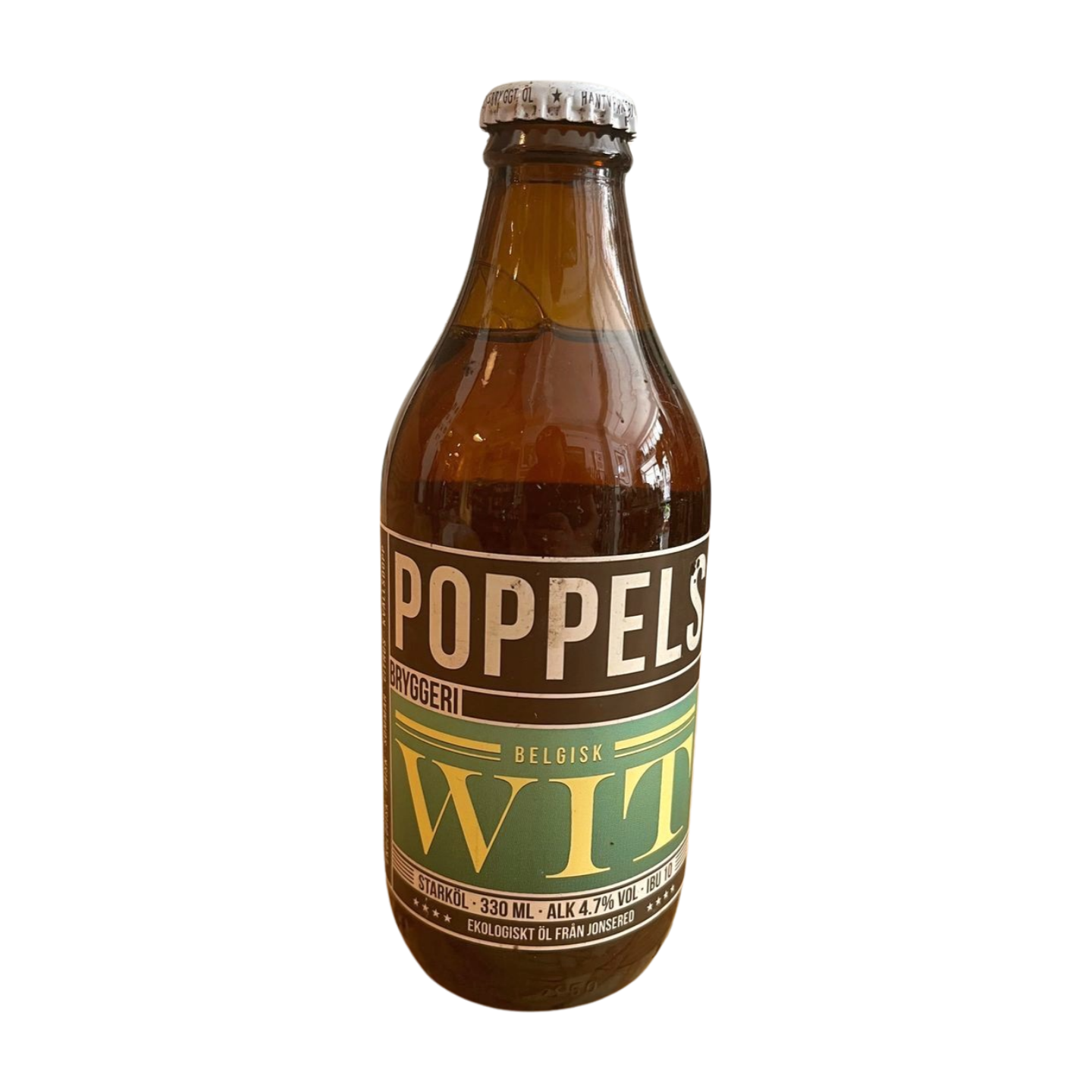

The production of beer is a multi-stage process centered around the fermentation of sugars derived from grains, primarily malted barley. This process typically involves malting (controlled germination of grains), milling (crushing the malt to expose starches), mashing (mixing the grist with hot water to convert starches into fermentable sugars, creating a sugary liquid called wort), lautering (separating the wort from the spent grains), boiling (sterilizing the wort and adding hops for bitterness, aroma, and flavor), whirlpooling (clarifying the wort by removing solids), cooling and aeration (preparing the wort for fermentation), fermentation (adding yeast to convert sugars into alcohol and carbon dioxide), conditioning (aging the beer to develop flavor and clarity), and finally, packaging (bottling, canning, or kegging).

In recent years, a growing emphasis on environmental responsibility has led beer producers to incorporate and explore various sustainable practices. Water conservation is a significant focus, with breweries implementing closed-loop systems, water recycling technologies, and dry cleaning methods to reduce water usage throughout the brewing process, from mashing to packaging. Energy efficiency is another key area, with breweries investing in energy-efficient equipment, utilizing renewable energy sources like solar power, and implementing heat recovery systems to reduce their carbon footprint. Waste reduction is also a priority, with initiatives such as repurposing spent grains as animal feed or fertilizer, choosing eco-friendly packaging materials, and implementing comprehensive recycling and composting programs. Some breweries are also focusing on sustainable sourcing of raw materials, opting for locally grown and organic ingredients to reduce transportation emissions and support environmentally friendly farming practices. Furthermore, carbon offsetting programs and investments in carbon capture technologies are being explored to mitigate the overall environmental impact of beer production. These efforts reflect a growing awareness within the brewing industry of the importance of environmental stewardship and a commitment to a more sustainable future for beer production.

Filters

Portuguese wine

Frequently asked questions

The entire country of Portugal is divided into 14 different wine regions, including in the Azores and Madeira islands. Some of Portugal's most famous winemaking regions include the Douro Valley (known for Port) and Vinho Verde (known for its light, refreshing white wines).

Portugal is becoming more well known for its orange wines, talha wines (traditionally made in clay pots), and palhete (made by blending red and white grapes together).

Portugal is best known for its fortified wine, called Port wine. It is produced in the Douro Valley, which is a UNESCO World Heritage Site and recognized as the world's first demarcated wine region, established in 1756.

Vinho Verde in northern Portugal is another popular winemaking region characterized by rolling hills and lush landscapes. It's known around the world for low-alcohol, refreshing white wines, although the region traditionally focused more on red wines made with the fruit-forward vinhão grape.

The Portuguese island of Madeira, with its subtropical climate, is renowned for its fortified wines. Winemaking here dates back to the 15th century, when Portuguese

explorers brought grape varieties from around the world.

Our sustainable, natural wine shop is located in the Marquês neighborhood in Porto, Portugal. We also ship to countries around the world, including within Europe, the United States, Canada, Australia, China, and more. Review our Shipping Policy to learn more.

In recent years, there has been a notable shift toward sustainable viticulture and the production of natural wine in Portugal. Many winemakers are implementing organic farming practices and embracing biodiversity to maintain soil health and reduce chemical inputs. This commitment to sustainability is not only beneficial for the environment but also enhances the quality of the wines, allowing the unique characteristics of the terroir to shine through. For example, some winemakers are now utilizing ancient terracotta amphorae for fermentation (called talha in Portuguese). This method preserves regional cultural heritage, enhances the wine's character, and aligns with sustainable practices by reducing reliance on modern materials.